Short Lead Time for 3m Adhesive Magnet - Permanent Lifting Magnet – Horizon Detail:

Permanent lifting magnet or permanent magnet lifter is a complicated magnetic system with high-performance Neodymium magnets. Through the rotation of the handle, the magnetic force is changed to hold and release the workpieces. The permanent magnetic lifter is a quick, safe and easy way to lift steel plates, iron blocks and cylindrical iron materials, such as mechanical parts, punch molds and various types of steel materials.

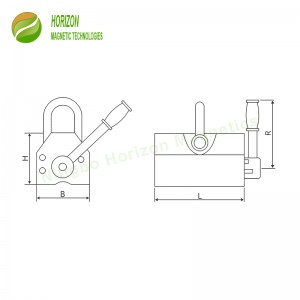

It is composed of two parts, permanent sucker and discharge device. The permanent sucker is made up of Neodymium permanent magnets and magnet-conductive plate. The magnetic force lines generated by the Neodymium magnets go through the magnet-conductive plate, attracted materials and form a closed circuit to achieve the purpose of lifting the steel materials. Discharge device mainly refers to the handle. It is widely used in the machinery industry, mold manufacturing, warehouses and transportation departments to transport steel plates, steel ingots and other magnetically conductive objects.

1.Compact size and light weight

2.Quick and easy to operate with ON/OFF system / handle

3.V-shaped groove design at the bottom enabling the same lifting magnet suitable for both flat and round objects

4.Force powered by super-strong grade of rare earth Neodymium magnets

5.Large chamfering around the bottom effectively protecting the flatness of the bottom surface and allowing the magnetic lifter to fully exert its magnetic force

| Part Number | Rated Lifting Strength | Maximum Pull-off Strength | L | B | H | R | Net Weight | Maximum Operating Temperature | |

| kg | kg | mm | mm | mm | mm | kg | °C | °F | |

| PML-100 | 100 | 250 | 92 | 65 | 69 | 155 | 2.5 | 80 | 176 |

| PML-200 | 200 | 550 | 130 | 65 | 69 | 155 | 3.5 | 80 | 176 |

| PML-300 | 300 | 1000 | 165 | 95 | 95 | 200 | 10.0 | 80 | 176 |

| PML-600 | 600 | 1500 | 210 | 115 | 116 | 230 | 19.0 | 80 | 176 |

| PML-1000 | 1000 | 2500 | 260 | 135 | 140 | 255 | 35.0 | 80 | 176 |

| PML-1500 | 1500 | 3600 | 340 | 135 | 140 | 255 | 45.0 | 80 | 176 |

| PML-2000 | 2000 | 4500 | 356 | 160 | 168 | 320 | 65.0 | 80 | 176 |

| PML-3000 | 3000 | 6300 | 444 | 160 | 166 | 380 | 85.0 | 80 | 176 |

| PML-4000 | 4000 | 8200 | 520 | 175 | 175 | 550 | 150.0 | 80 | 176 |

| PML-5000 | 5000 | 11000 | 620 | 220 | 220 | 600 | 210.0 | 80 | 176 |

1. Prior to lifting, clean the surface of the workpiece to be lifted. The center line of the permanent lifting magnets should coincide with the center of gravity of the workpiece.

2. In the lifting process, overloading, people under the workpiece or severe vibration is prohibited strictly. The temperature of the work piece and the ambient temperature should be lower than 80C degrees.

3. When lifting a cylindrical workpiece, the V-groove and the workpiece should be kept in contact with two straight lines. Its lifting capacity is only 30% – 50% of rated lifting strength.

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for Short Lead Time for 3m Adhesive Magnet - Permanent Lifting Magnet – Horizon, The product will supply to all over the world, such as: Egypt, Brazil, Egypt, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.