It is composed of rubber outside, inside Neodymium magnets, steel stud and steel plate. Unlike the general pot magnet with only one big powerful magnet encased inside the pot shell, generally the rubber coated magnet with external stud is produced with several smaller separate Neodymium disc magnets fixed onto one steel plate. The Neodymium magnets are not placed randomly, but positioned according to carefully designed circuit so as to make the whole rubber coated pot magnet with a stronger holding force. The protective rubber coating covers all the surface of the Neodymium magnets and steel plate, except the external stud left.

1. It can be the best option to fulfill the holding purpose on the delicate surface without damage because the soft rubber coating may prevent from surface scratches and provide a higher slip resistance. e.g. holding Led lights on off road trucks or cars.

2. In some wet or some chemical corrosion environment, the rubber coating can protect Neodymium magnet from exposing in the corrosion environment directly to extend its service time.

3. Steel external stud makes the rubber coated Neodymium magnet easy to mount objects with threaded holes.

1. Genuine Neodymium magnet material and standard magnetic properties, magnet size and force NEVER smaller than requirement

2. Standard sizes in stock and available for immediately delivery

3. Many types of magnets and Neodymium magnetic systems produced in-house to meet one-stop source of magnetic products

4. Custom-made solutions available upon request

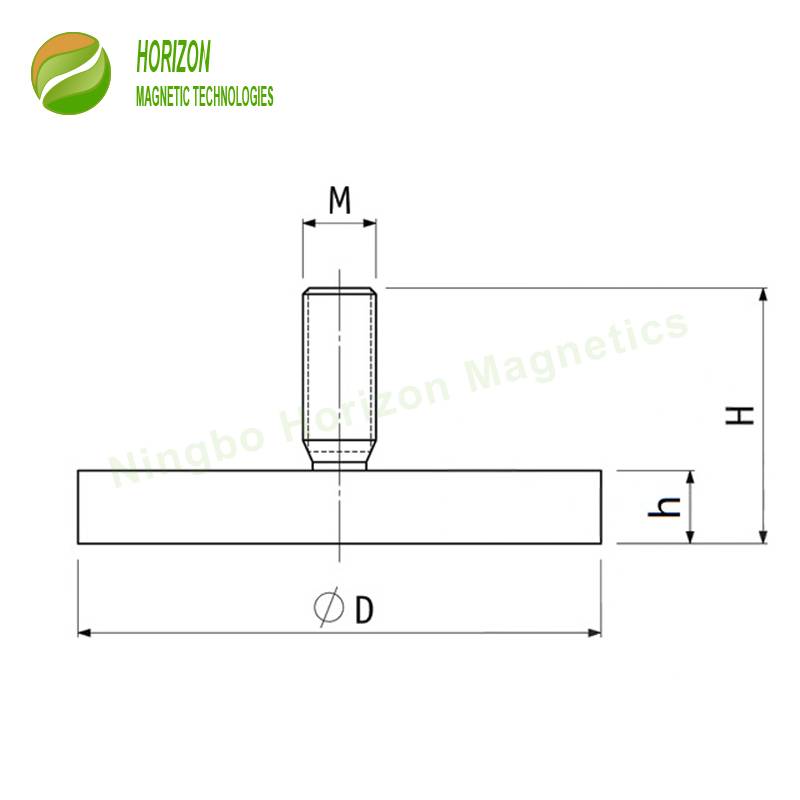

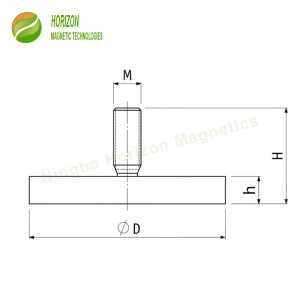

| Part Number | D | M | H | h | Force | Net Weight | Maximum Operating Temperature | ||

| mm | mm | mm | mm | kg | lbs | g | °C | °F | |

| HM-H22 | 22 | 4 | 12.5 | 6 | 5 | 11 | 15 | 80 | 176 |

| HM-H34 | 34 | 4 | 12.5 | 6 | 7.5 | 16.5 | 26 | 80 | 176 |

| HM-H43 | 43 | 6 | 21 | 6 | 8.5 | 18.5 | 36 | 80 | 176 |

| HM-H66 | 66 | 8 | 23.5 | 8.5 | 18.5 | 40 | 107 | 80 | 176 |

| HM-H88 | 88 | 8 | 23.5 | 8.5 | 43 | 95 | 193 | 80 | 176 |