OEM Supply Countersunk Magnet - Neodymium Block Magnet – Horizon Detail:

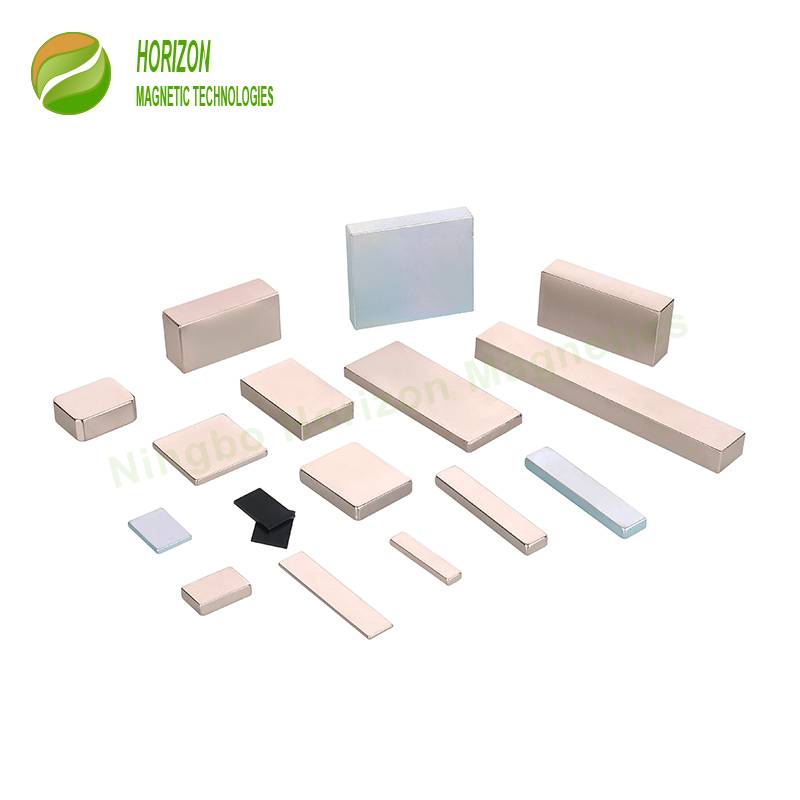

Neodymium block magnet is called as block Neodymium magnet, NdFeB block magnet, or Neodymium rectangular magnet. It is a rectangle shape, and is the most common shape of Neodymium magnet.

Most sizes of Neodymium block magnets are machined from a large magnet block. How is the large Neodymium magnet block produced? In fact, the production process for rare earth Neodymium magnet belongs to powder metallurgy. In this process, a suitable composition of raw materials are pulverized into fine powder, pressed and heated to cause densification via liquid phase sintering, which is the reason that it is often called sintered rare earth magnet. Through melting, jet milling, sintering and aging, a large magnet block or semi-finished Neodymium magnet block is produced with a rough surface and only approximate dimensions.

In order to get the final Neodymium block magnet with smaller and more accurate size, the large magnet block will enter into the machining process, if the magnetic properties are tested OK to meet the requirement. During the machining process, more attention should be paid to size, tolerance, and especially the orientation direction so as to ensure Neodymium block magnet quality.

If the size of the final Neodymium block magnet is big, for example, 100 x 60 x 50 mm, the semi-finished magnet size will be produced similar to the final size, because it’s not easy or economical to produce a semi-finished magnet which can be machined to several or even two final block magnets. The simple grinding process may machine one semi-finished magnet to one final Neodymium block magnet!

Neodymium block magnet has three directions, like length, width and thickness, and generally the Neodymium magnet size is described as L x W x T, such as 30 x 10 x 5 mm. Generally speaking, the shortest one of the three dimensions is the orientation direction. However in many cases the customers might have specific requirement about the orientation, for example for the longest dimension, or multi poles on the same surface…

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for OEM Supply Countersunk Magnet - Neodymium Block Magnet – Horizon, The product will supply to all over the world, such as: Johannesburg, Lahore, Durban, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!