Generally speaking, the round magnet with diameter smaller than 3mm, disc or block magnet with thickness shorter than 1mm, the machining technology or quality control will be quite different from general sized magnets, and then they may be regarded as tiny or micro magnets.

Considering the sintered NdFeB magnet has some distinct requirements about magnetic properties and surface treatment different from other general machining parts, the tiny Neodymium magnet is not easy to produce, machine or inspect to ensure a required quality finished Neodymium micro magnet.

Neodymium tiny magnet is more difficult to produce than being imagined. Some people might think that the micro Neodymium magnet only needs more attention during the machining process, but the fact is quite different. The magnetic properties, and magnetic field strength or magnetic flux might vary large for same sized magnets with thin thickness. Most people think the machining tolerance between each magnet causes the magnet size or volume with smaller difference and then smaller difference in magnetic field strength. However, the magnetic properties between thin magnets are bigger than thicker magnets, if the magnetic properties can not be controlled well within each magnet block, between each magnet block and between lots of magnet blocks.

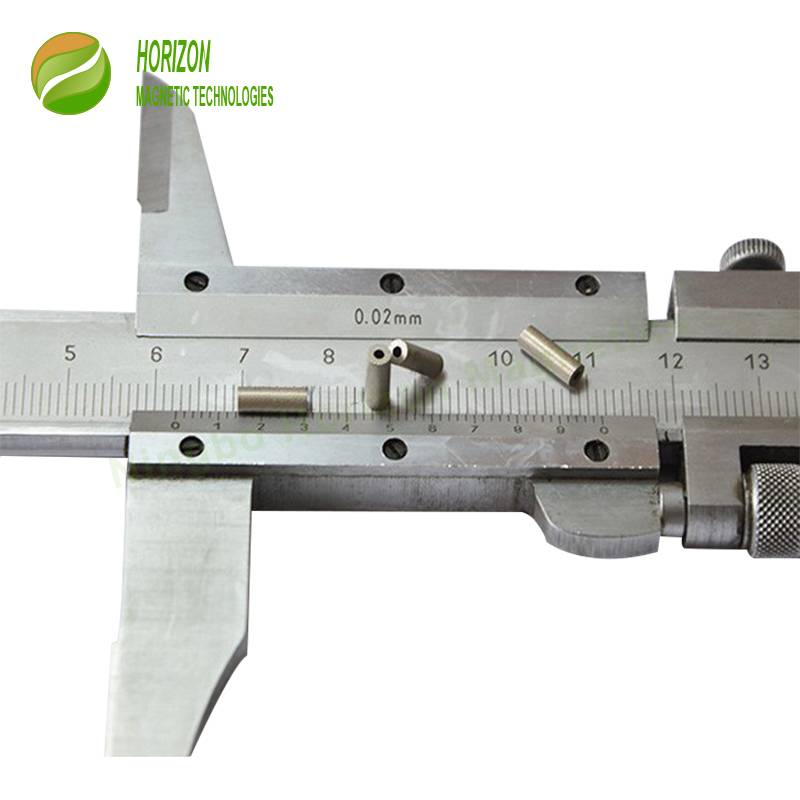

Thanks to our precision processing equipments, over 10 year experienced machining engineers, and experienced knowledge in supplying customers with countless tiny Neodymium magnets in the past decade, Horizon Magnetics have the capability to produce and control the quality through all the production and QC processes, including magnet block production, machining, plating, magnetization, inspection, etc. At this moment, we can control the sintered Neodymium micro magnets with tiny diameter of 0.2mm and tiny thickness with 0.15mm subject to your Neodymium magnet shape and overall dimensions in each direction.