Generally speaking, the exact dimension for the Neodymium ring magnet can be described exactly with all three related sizes, like outer diameter (OD or D), inner diameter (ID or d) and the length or thickness (L or T), for example OD55 x ID32 x T10 mm or simply as D55 x d32 x 10 mm.

For Neodymium ring magnet, the production technology is more difficult or has more options than simple block shaped magnets. What production technology should be chosen depends on several factors including the ring magnet dimension, magnetization direction, scrap rate and then production cost at least. The ring magnet may have three types of magnetization direction, radially magnetized, diametrically magnetized and axially magnetized.

In theory, the magnetic properties of an entire radial magnetized ring are better than assembled ring composed of several magnet segments diametrical magnetized in pair. But the production technology for radial ring of sintered Neodymium magnet still has many obstacles, and the sintered radial ring magnet in production has many requirement limits to lower properties, smaller size, higher scrap rate, more expensive tooling charge starting from the sampling stage, and then higher price, etc. In most applications, in the end the customers decide to use diametrical magnetized segments of sintered Neodymium magnets to form a ring or only bonded Neodymium magnet ring instead. Therefore the actual market for sintered Neodymium magnet radial ring is very small compared to the general ring or diametrically magnetized segments of Neodymium magnets.

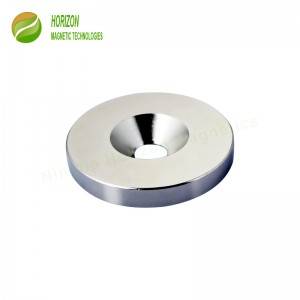

If the order quantity is not big, generally the Neodymium ring magnet orientated via diameter is machined from a large rectangular magnet block rather than from a ring shaped magnet block. Although the machining cost from a block shape to a ring shape is higher, the production cost for rectangular magnet block is much lower than diametrically orientated ring or cylinder magnet. Neodymium magnet ring is widely used in loudspeakers, fishing magnets, hook magnets, precast insert magnets, pot magnets with borehole, etc.