According to detailed requirement like shape, size, holding force, etc, we calculate and find out the steel dimension, Neodymium magnet grade and matching size. Sometimes, N35 grade of Neodymium magnet cannot reach enough holding force to meet requirements, and then higher grade must be supplied instead. The shape, size and position of the holes must be controlled strictly during machining and plating the steel house. Before assembling the channel magnets, the quality and holes for both magnets and steel u-channels must be strictly inspected. In the assembling and final inspection processes, the matching position of holes between Neodymium magnets and steel channels must be checked too and verified via M3 screw.

1.Directly mount the steel face on walls or required places with M3 screws firmly.

2.It’s easy to hold ferromagnetic hardware, such as wrenches, hammers, screwdrivers, knives, kitchen tools, clamps, etc on the surface of channel magnet.

3.It’s widely used in many fields, such as garages, workstations, butcher shops, kitchens, even trucks inside.

4.The brittle Neodymium magnet is protected by the u shape steel housing from physical damage outside, which enables the channel magnet to work over and over.

5.The steel channel redirects one polarity of powerful Neodymium magnet to the other needed contact side to increase stronger holding force.

6.There are many options of size and holding force, and customized options to fulfill your diverse requirements.

1. Material: high performance Neodymium magnet + A3 steel + glue

2. Coating: normally three layers of Ni+Cu+Ni coating to enhance corrosion resistance, but customized coating available upon request

3. Size and force: referring to size specification, and customized Neodymium rectangular channel mounting magnets available upon request

1. High quality: NdFeB magnet, especially quality of countersunk holes, the most important component is produced by our own factory, which enables us to make magnet quality under control.

2. Fast delivery: Enough channel magnets inventory and in-house fabricating capacity enables a just-in-time delivery.

3. More options: More standard options are available. Moreover, our in-house production and fabrication enables customized options of magnetic systems for customers conveniently. We can meet simple one-stop purchase.

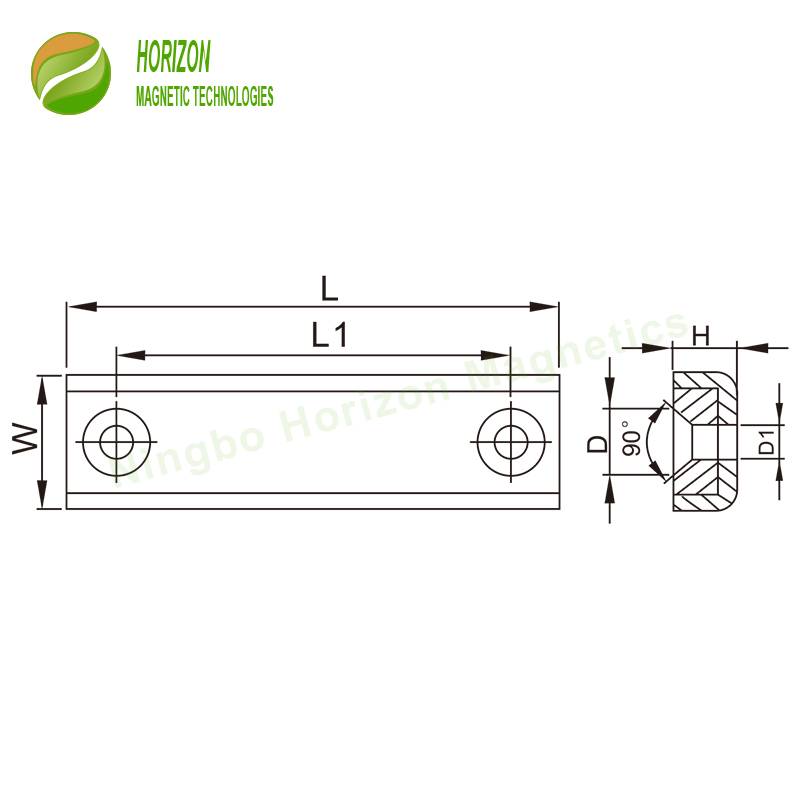

| Part Number | L | L1 | W | H | D | D1 | Force | Net Weight | Maximum Operating Temperature | ||

| mm | mm | mm | mm | mm | mm | kg | lbs | g | °C | °F | |

| HM-CM-040 | 40 | 30 | 13.5 | 5 | 6.5 | 3.3 | 17 | 37 | 18.4 | 80 | 176 |

| HM-CM-050 | 50 | 40 | 13.5 | 5 | 6.5 | 3.3 | 27 | 59 | 23.2 | 80 | 176 |

| HM-CM-060 | 60 | 50 | 13.5 | 5 | 6.5 | 3.3 | 30 | 66 | 27.9 | 80 | 176 |

| HM-CM-070 | 70 | 60 | 13.5 | 5 | 6.5 | 3.3 | 31 | 68 | 31.2 | 80 | 176 |

| HM-CM-080 | 80 | 70 | 13.5 | 5 | 6.5 | 3.3 | 33 | 72 | 37.8 | 80 | 176 |

| HM-CM-090 | 90 | 80 | 13.5 | 5 | 6.5 | 3.3 | 35 | 77 | 41.2 | 80 | 176 |

| HM-CM-100 | 100 | 90 | 13.5 | 5 | 6.5 | 3.3 | 36 | 79 | 46.9 | 80 | 176 |

| HM-CM-110 | 110 | 100 | 13.5 | 5 | 6.5 | 3.3 | 38 | 83 | 49.2 | 80 | 176 |

| HM-CM-120 | 120 | 110 | 13.5 | 5 | 6.5 | 3.3 | 40 | 88 | 56.5 | 80 | 176 |