Massive Selection for Precast Magnets - Insert Magnet – Horizon Detail:

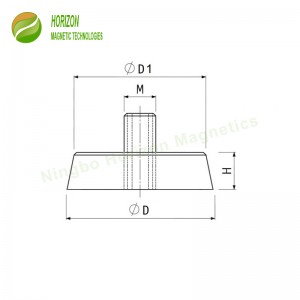

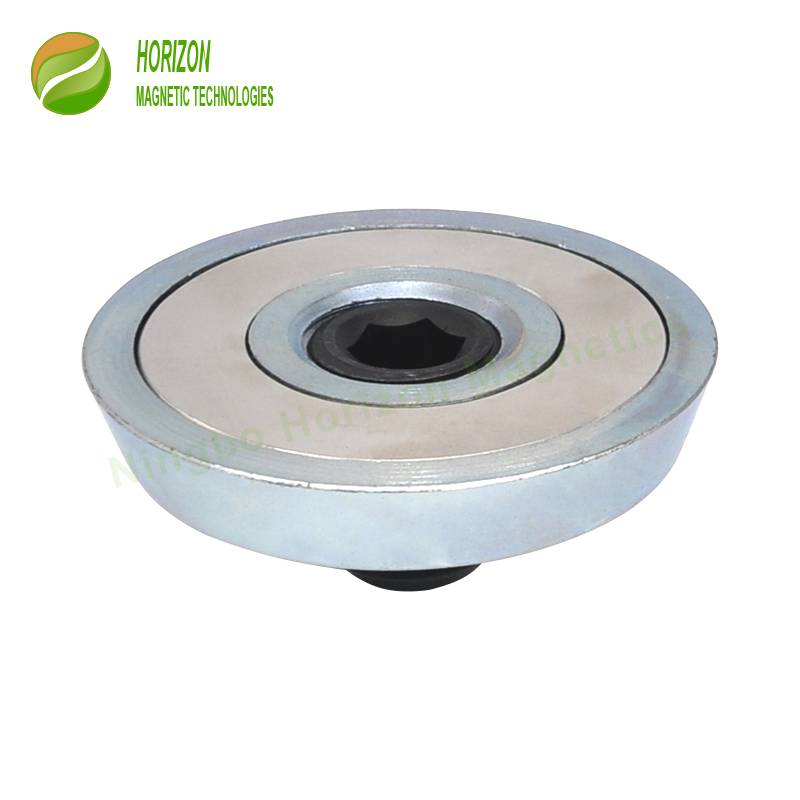

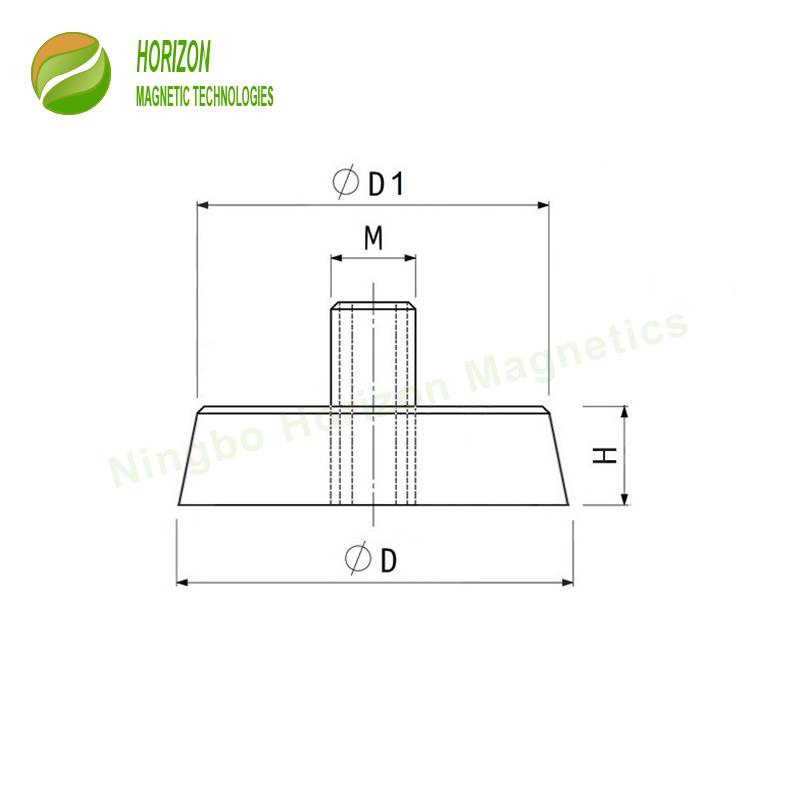

Just same as the pot magnet, the insert magnet consists of a ring NdFeB magnet, steel casing and threaded rod. The steel casing protects Neodymium magnet from outside damage and concentrates the magnetic forces of the encased Neodymium ring magnet to the contacted surface only to generate much higher force than a separate Neodymium magnet. However it has some different points from the pot magnet so as to meet the application requirement in precast concrete. The shape of the steel casing is tapered and the threaded rod is interchangeable so that the insert magnet is convenient to detach from the hardened concrete through the socket wrench.

1. Material: Neodymium magnet with high performance and grade + Steel casing and rod

2. Coating: Magnet coated with NiCuNi or Zinc + steel casing coated with Zinc or Copper

3. Size and force: Referring to Technical Data

4. Package: Packed in corrugated cartons. Cartons packed in wooden pallet or case for large quantity

1. Magnetic power and unique design and structure enable light and easy to operate.

2. It is reusable and durable to save cost shared in long term.

3. It is quick to position and improve efficiency and cost.

4. It can improve quality of precast concrete elements.

5. Magnet power is high enough to position and fasten the embedded components accurately during concrete casting or vibrating process to enable safe lifting operation.

1. Unbeatable know-how in Neodymium magnet, the most important component to ensure insert magnet quality

2. Knowledge in magnetics and in-house fabricating helping customers realize customers’ products from the concept to final magnetic products conveniently

3. More styles and sizes available to save tooling cost and product price for customers

4. Standard sizes in stock and available for immediately delivery

5. Complete supply of precast concrete magnets including shuttering magnets, magnetic chamfers and custom-made magnetic products to meet customers’ one-stop purchase

| Part Number | D | D1 | H | M | Maximum Operating Temperature | |

| mm | mm | mm | mm | °C | °F | |

| HM-IN45-M8 | 45 | 40 | 8 | 8 | 80 | 176 |

| HM-IN45-M10 | 45 | 40 | 8 | 10 | 80 | 176 |

| HM-IN54-M12 | 54 | 48 | 10 | 12 | 80 | 176 |

| HM-IN54-M16 | 54 | 48 | 10 | 16 | 80 | 176 |

| HM-IN60-M20 | 60 | 54 | 10 | 20 | 80 | 176 |

| HM-IN77-M24 | 77 | 73 | 12 | 24 | 80 | 176 |

1. Avoid grout covering surface of the encased Neodymium magnet to keep magnetic force.

2. Operate or store the insert magnet below 80℃. Higher temperature may cause the magnet to reduce or totally lose magnetic force.

3. It is highly recommended that gloves should be worn to protect operators’ hands from pinching on impact. Please keep it far away from electronic instruments and unnecessary ferromagnetic metals. Special caution should be exercised if someone is wearing a pacemaker, because strong magnetic fields can damage the electronics inside pacemakers.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Massive Selection for Precast Magnets - Insert Magnet – Horizon, The product will supply to all over the world, such as: Munich, Canberra, Rio de Janeiro, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!