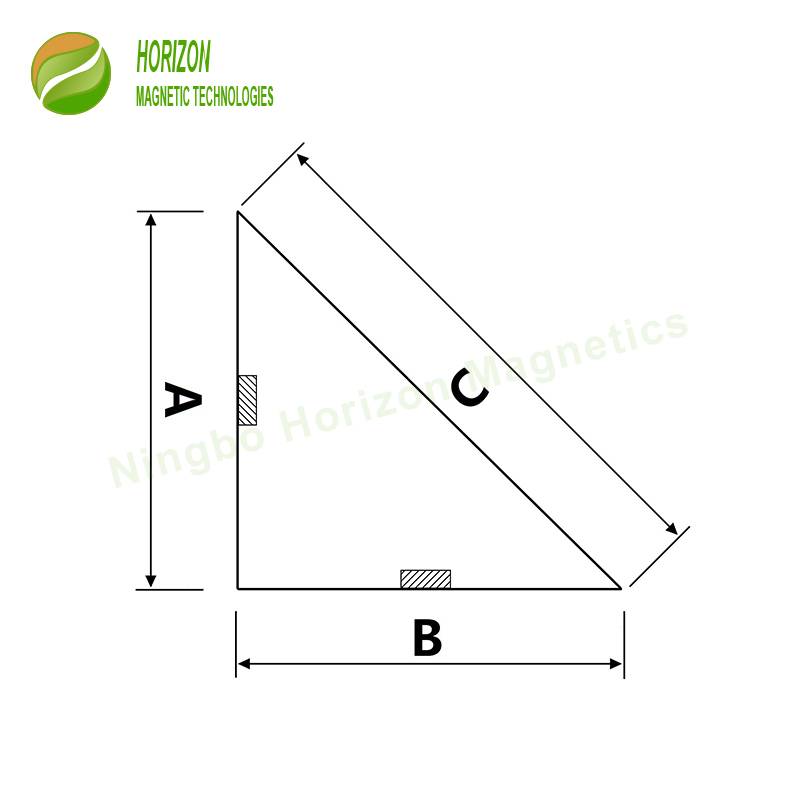

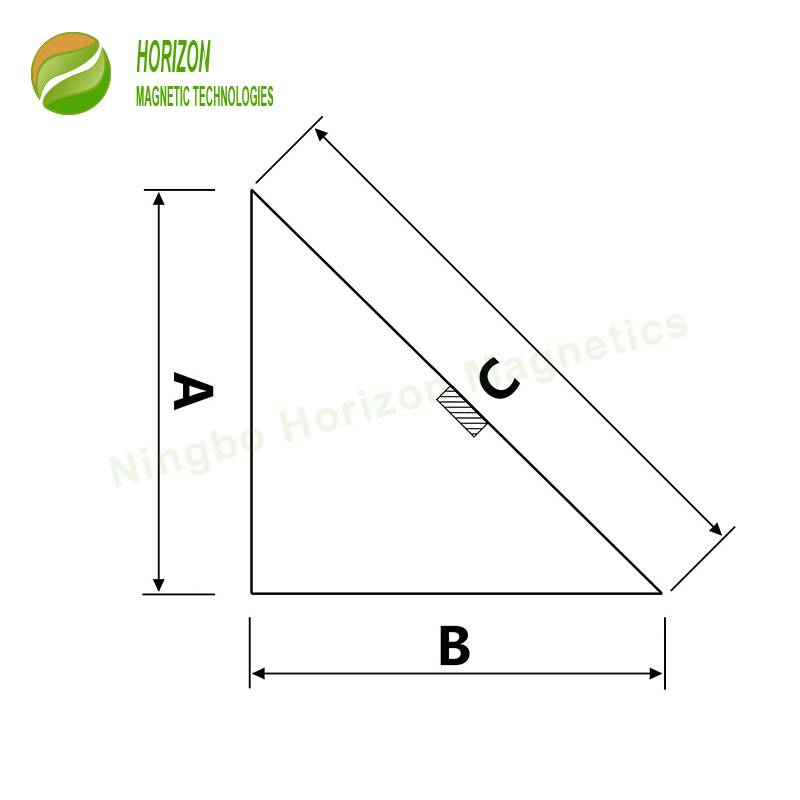

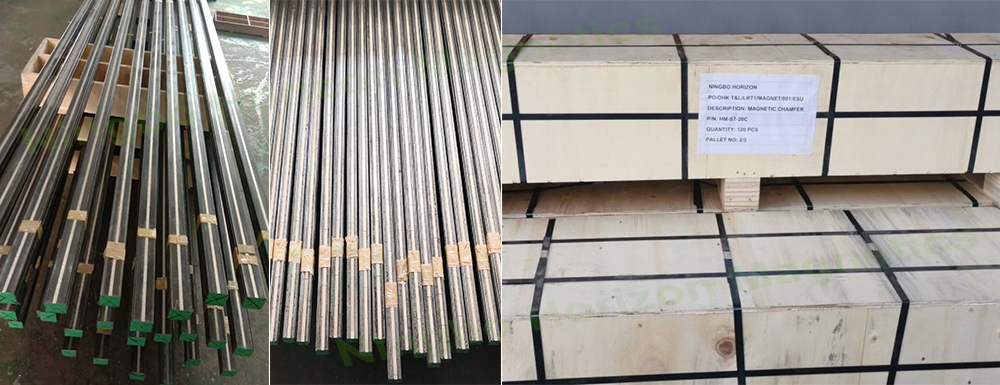

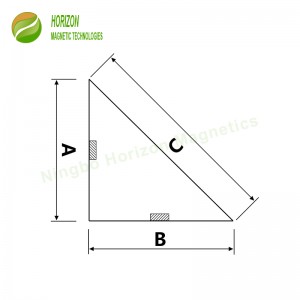

It is made of strong Neodymium bar magnets embedded in the high quality steel. Just as the structure and principle of Neodymium channel magnets, the steel redirects the polarity of the Neodymium magnets from one side to the other contacted side with higher holding force. Moreover, many small bar magnets are protected by the steel from the mechanical damage. The contact side enables a fast and accurate placement of the steel chamfer in steel formwork construction without slipping or sliding. The magnetic chamfer is isosceles right triangle shaped and can be delivered in several different sizes with magnets on single side, double sides or the hypotenuse along the full 100% length or just along 50% of the length.

1. Easy to operate

2. Reusable and durable to minimize investment shared in long term

3. No screws, bolts, welding or electricity necessary to fasten the magnetic chamfer. Quick to position, remove and clean

4. Universal with most precast concrete systems to reduce quantity purchase and cost for different systems

5. Much stronger adhesive force and longer service life than the rubber chamfer

6. Improving quality result on the precast concrete products to eliminate much of the building finish problems

1. Unrivaled competitive strength magnetic and application in precast concrete industry and familiar with what and how to ensure steel magnetic chamfers, shuttering magnets and insert magnets to solve customers’ concerns

2. More sizes available to save tooling cost and then product price for customers

3. Standard sizes in stock and available for immediately delivery

4. Custom-made solutions available upon request

5. Many magnetic chamfers popular with customers and some of our models recognized as the standard design or size in the precast concrete industry.

| Part Number | A | B | C | Length | Length of Magnet | Type of Magnetized Side | Maximum Operating Temperature | |

| mm | mm | mm | mm | °C | °F | |||

| HM-ST-10A | 10 | 10 | 14 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-10B | 10 | 10 | 14 | 3000 | 50% or 100% | Double | 80 | 176 |

| HM-ST-10C | 10 | 10 | 14 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-15A | 15 | 15 | 21 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-15B | 15 | 15 | 21 | 3000 | 50% or 100% | Double | 80 | 176 |

| HM-ST-15C | 15 | 15 | 21 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-20A | 20 | 20 | 28 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-20B | 20 | 20 | 28 | 3000 | 50% or 100% | Double | 80 | 176 |

| HM-ST-20C | 20 | 20 | 28 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-25A | 25 | 25 | 35 | 3000 | 50% or 100% | Single | 80 | 176 |

| HM-ST-25B | 25 | 25 | 35 | 3000 | 50% or 100% | Double | 80 | 176 |

1. Place the magnetic chamfer on the formworks gently so as to avoid magnets damaged by the sudden attracting.

2. The embedded Neodymium magnets must be kept clean. Avoid grout covering the magnets so as to keep magnetic force.

3. After use, it should be kept clean and oiled so as to being protected from corrosion.

4. The max operating or storage temperature must be below 80℃. Higher temperature may cause magnetic chamfer to reduce or totally lose magnetic force.

5. Although the magnetic force of magnetic steel triangle chamfer is much lower than shuttering magnet, it is still strong enough to create hazards to personnel through pinching on impact. Wearing gloves to protect one's hands is highly recommended. Please keep it far away from electronic instruments and unnecessary ferromagnetic metals. Special caution should be exercised if someone is wearing a pacemaker, because strong magnetic fields can damage the electronics inside pacemakers.