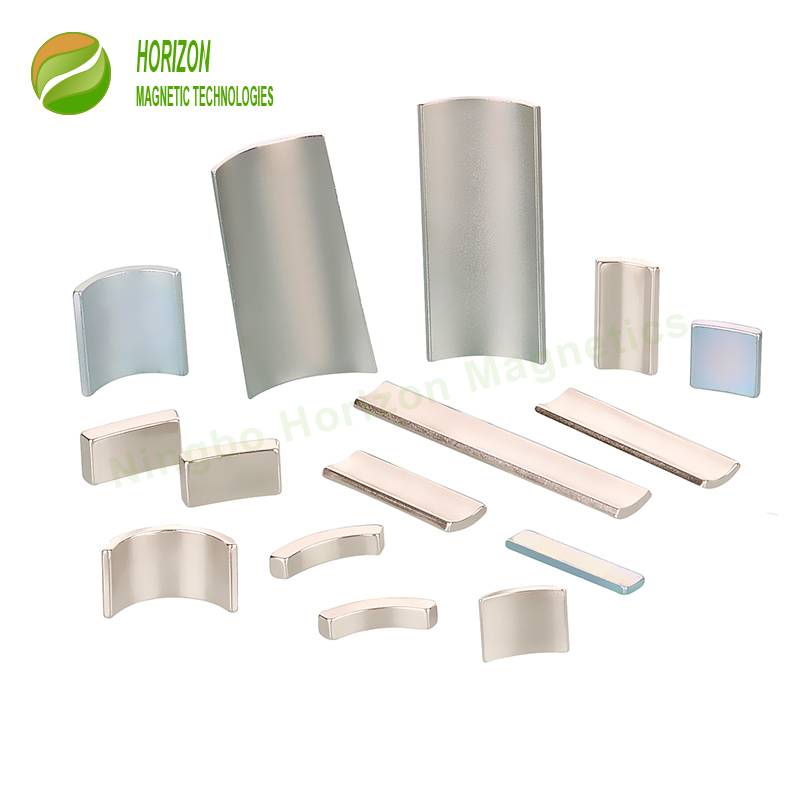

High definition Neodymium Cylinder Magnet - Neodymium Arc Magnet – Horizon Detail:

Neodymium arc magnet, segment magnet or magnetic tile is a special shape of sintered Neodymium magnet, which is mainly used for the industrial production. Unlike the shape of round or block magnets for versatile use for the common consumers in daily life, most of the arc Neodymium magnets, segment Neodymium magnets or Neodymium segment magnets are produced according to customers’ specific requirement on the grade, coating and especially size.

It requires more dimension factors to describe exact size for the segment magnet than the round or block magnet. A general segment magnet size description should include following sizes: outer diameter (OD or D) or outer radius (OR or R), inner diameter (ID or d) or inner radius (IR or r), angle (°) or width (W), and length (L), for example R301 x r291 x W53 x L94 mm. If the arc magnet has a special angle, or outer diameter and inner diameter don’t share the same center, the size description should need more sizes like thickness, or drawing to show the detailed dimension. Because of the complicated requirement about the size, almost all the Neodymium arc magnets are customized.

Generally speaking, the sintered Neodymium arc magnet is produced by EDM and / or profile grinding from a block shaped magnet blocks. And the length of the arc magnet may be cut to required several arc magnets with shorter length. The general size limit for a segment Neodymium magnet is following for reference:

Normal size range: L (Length): 1 ~ 180 mm, W (Width): 3 ~ 180 mm, H (Height): 1.5 ~ 100 mm

Maximum size: L50 x W180 x H80 mm, L180 x W80 x H50 mm,

Minimum size: L1 x W3 x H2 mm

Orientation direction size: Lower than 80 mm

Tolerance: Generally +/-0.1 mm, Particularly +/-0.03 mm

For the industrial applications, the Neodymium arc magnet is mainly used to glue, assemble or fix the inner radius face of the magnet on a shaft to work as a rotor for the electric motor. Sometimes, the outer radius face of the arc magnet is fixed to a housing to work a stator for the electric motor. The typical industrial application for the Neodymium segment magnets is a motor rotor, electric motor, magnetic pump coupling, etc.

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for High definition Neodymium Cylinder Magnet - Neodymium Arc Magnet – Horizon, The product will supply to all over the world, such as: Angola, Sri Lanka, San Diego, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.