In the past, grade 30 or 32 was the highest Samarium Cobalt grade that almost all China SmCo magnet suppliers could supply. 35 grade Samarium Cobalt was dominated by some US companies, like Arnold (Arnold Magnetic Technologies, grade RECOMA 35E), EEC (Electron Energy Corporation, 34 grade SmCo). Horizon Magnetics is one of very few magnet companies that could supply grade 35 SmCo magnets in mass quantity with Br > 11.7 kGs, (BH)max > 33 MGOe and Hcb >10.8 kOe.

1. More power but lower weight. For Samarium Cobalt, this grade maximizes the energy density so as to fit some critical applications where smaller size and performance improvement is a priority

2. High stability. For this grade, BHmax, Hc and Br is higher than previous high grades of Sm2Co17 magnets like 32 grade, and temperature stability and maximum working temperature becomes better.

1. Motorsports: In the motorsports, it’s the ultimate purpose to win the fierce competition via taking advantage of innovative materials to maximize the torque and acceleration with the smallest and most stable package.

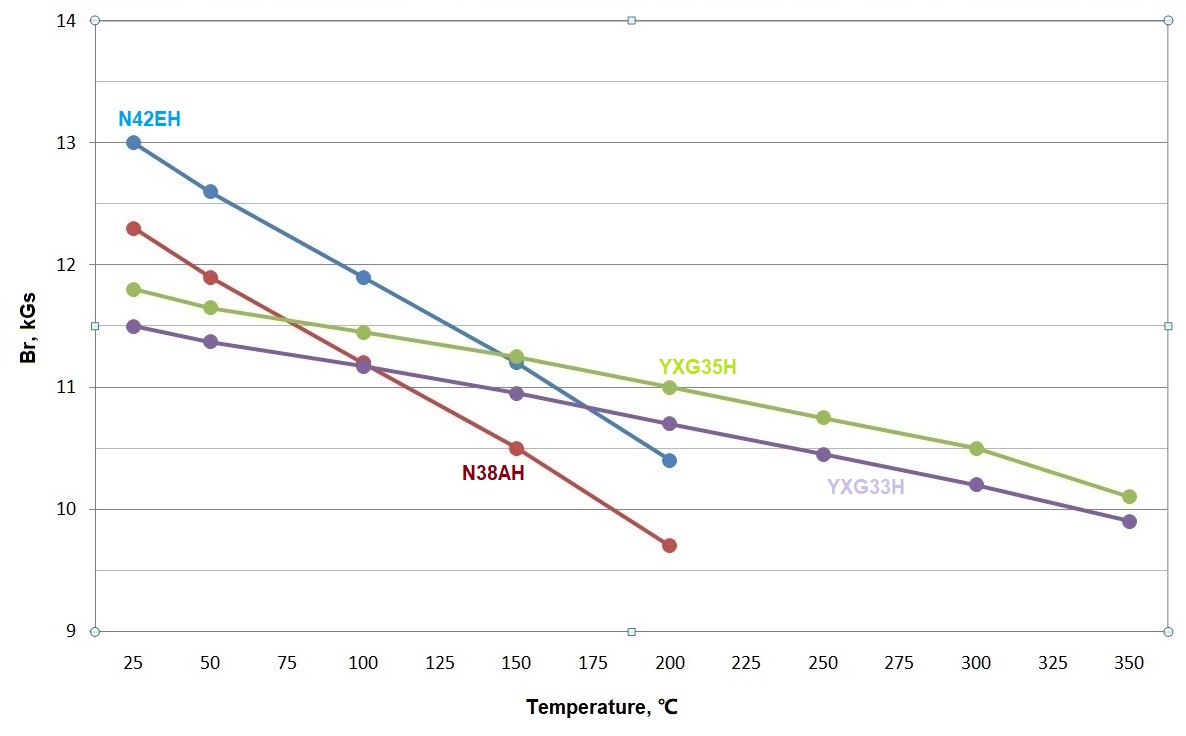

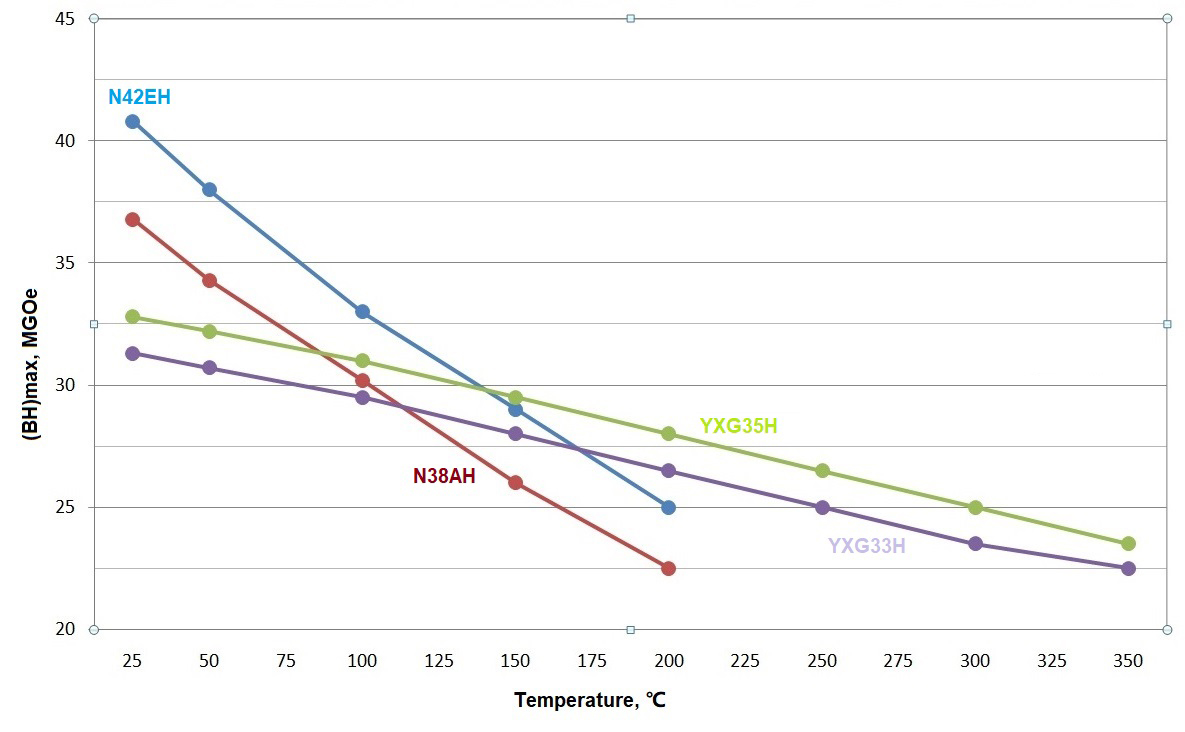

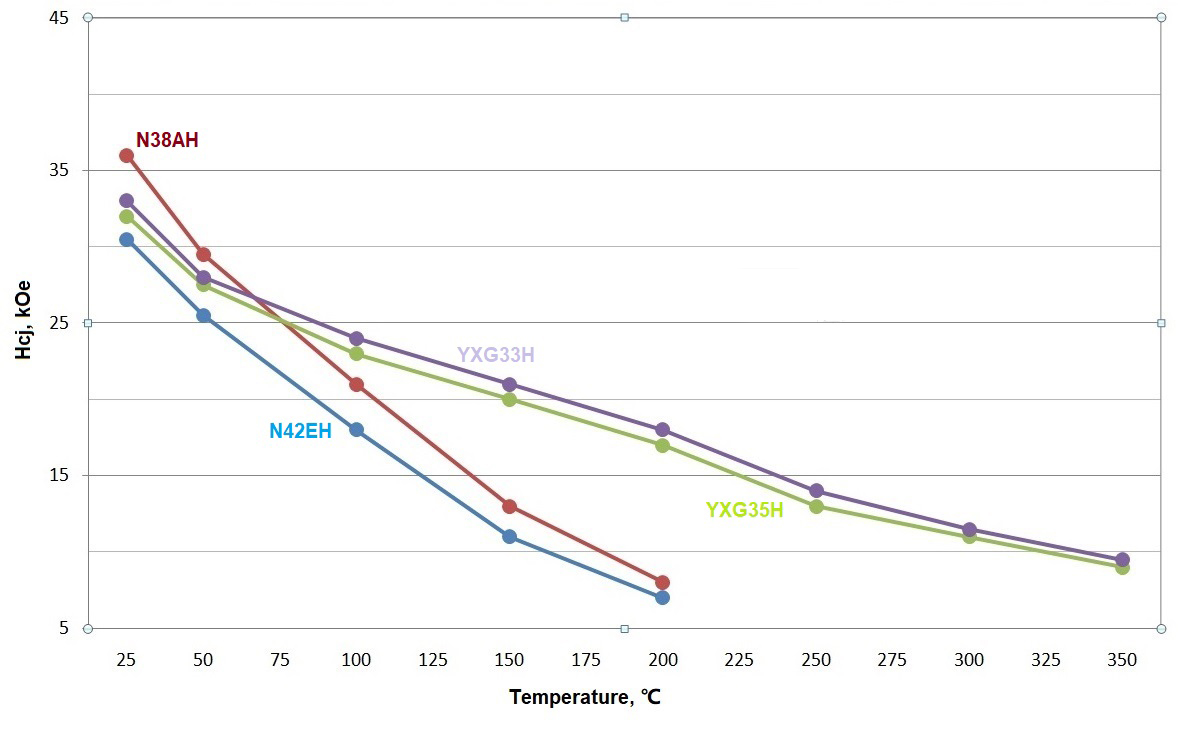

2. Replacing high performance Neodymium magnets: In most time, Samarium Cobalt price is more expensive than Neodymium magnet, so Samarium Cobalt magnet is mainly used for the markets where Neodymium magnet is not competent enough to meet the critical requirement. Heavy rare earth Dy (Dysprosium) and Tb (Terbium) has small reserve in limited countries but necessary for the high end Neodymium magnets including grade AH, EH or even UH, most of which are used in many electric motors. 2011 witnessed the crazy rise of raw material rare earth price. When rare earth price is going up, 35 grade Samarium Cobalt, or even 30 grade could be the best alternative magnet material for magnet users to remain more stable cost compared to their competitors. Due to excellent temperature stability, BHmax for grade 35 Samarium Cobalt becomes better than N42EH or N38AH of Neodymium magnet at temperatures exceeding 150C degree, which can be proved in the Hysteresis Curves.