Factory directly Laminated Samarium Cobalt Magnet – Grade 35 SmCo Magnet – Horizon Detail:

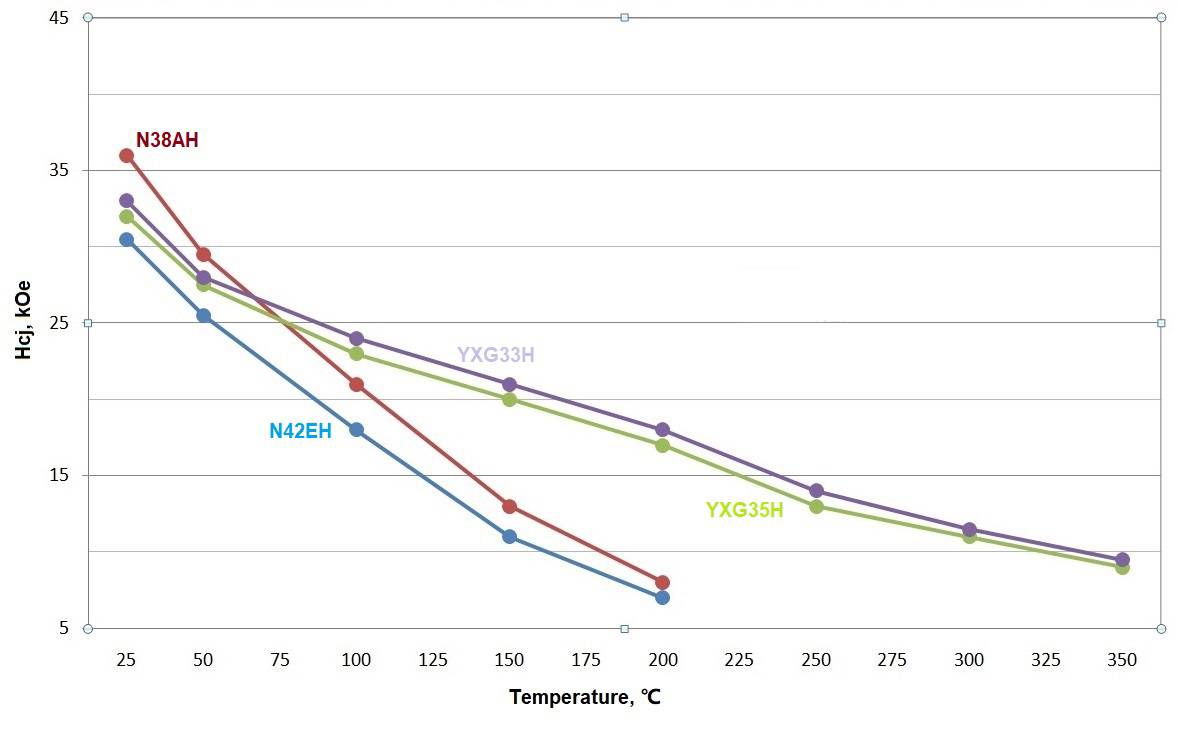

Grade 35 SmCo magnet or grade 35 Samarium Cobalt magnet is currently the most powerful Samarium Cobalt magnet on the market. It’s special high SmCo material providing a superior energy product, corrosion resistance, excellent temperature stability and temperature demagnetization resistance.

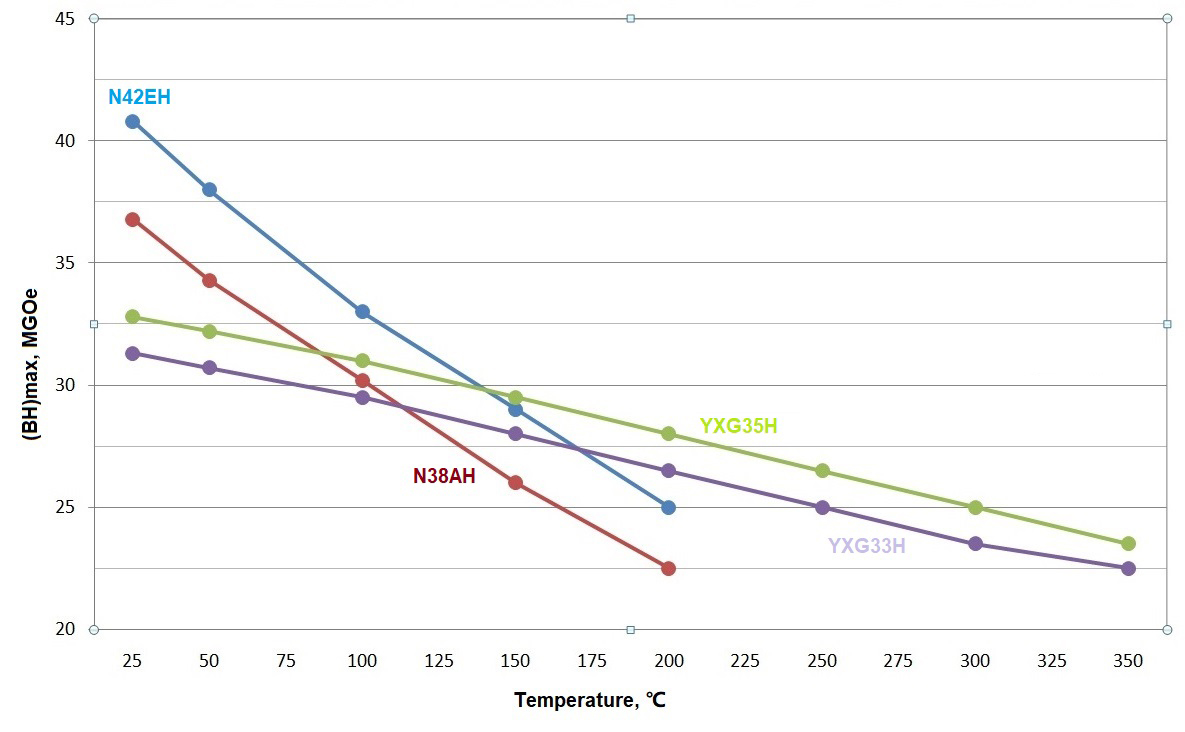

In the past, grade 30 or 32 was the highest Samarium Cobalt grade that almost all China SmCo magnet suppliers could supply. 35 grade Samarium Cobalt was dominated by some US companies, like Arnold (Arnold Magnetic Technologies, grade RECOMA 35E), EEC (Electron Energy Corporation, 34 grade SmCo). Horizon Magnetics is one of very few magnet companies that could supply grade 35 SmCo magnets in mass quantity with Br > 11.7 kGs, (BH)max > 33 MGOe and Hcb >10.8 kOe.

1. More power but lower weight. For Samarium Cobalt, this grade maximizes the energy density so as to fit some critical applications where smaller size and performance improvement is a priority

2. High stability. For this grade, BHmax, Hc and Br is higher than previous high grades of Sm2Co17 magnets like 32 grade, and temperature stability and maximum working temperature becomes better.

1. Motorsports: In the motorsports, it’s the ultimate purpose to win the fierce competition via taking advantage of innovative materials to maximize the torque and acceleration with the smallest and most stable package.

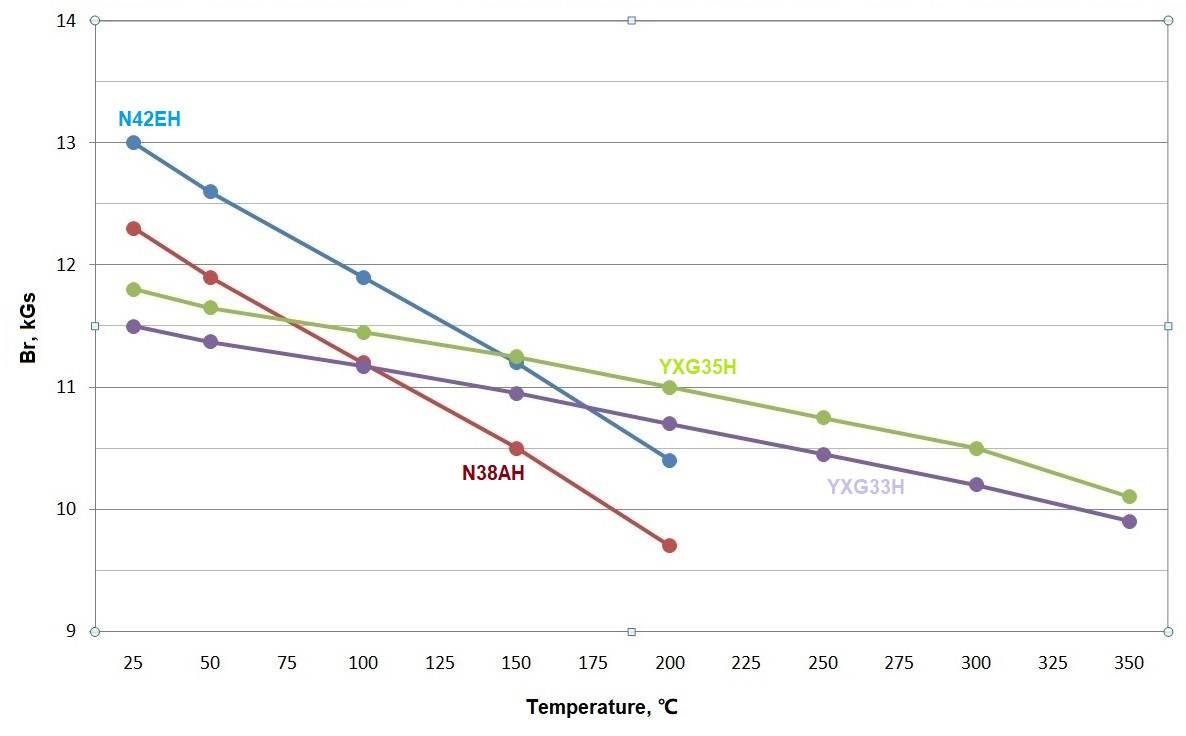

2. Replacing high performance Neodymium magnets: In most time, Samarium Cobalt price is more expensive than Neodymium magnet, so Samarium Cobalt magnet is mainly used for the markets where Neodymium magnet is not competent enough to meet the critical requirement. Heavy rare earth Dy (Dysprosium) and Tb (Terbium) has small reserve in limited countries but necessary for the high end Neodymium magnets including grade AH, EH or even UH, most of which are used in many electric motors. 2011 witnessed the crazy rise of rare earth price. When rare earth price is going up, 35 grade Samarium Cobalt, or even 30 grade could be the best alternative magnet material for magnet users to remain more stable cost compared to their competitors. Due to excellent temperature stability, BHmax for grade 35 Samarium Cobalt becomes better than N42EH or N38AH of Neodymium magnet at temperatures exceeding 150C degree.

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Factory directly Laminated Samarium Cobalt Magnet – Grade 35 SmCo Magnet – Horizon, The product will supply to all over the world, such as: Detroit, Croatia, Istanbul, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.