Strong NdFeB and SmCo magnets can generate power to drive some objects without any direct contact, so many applications take advantage of this feature, typically like magnetic couplings and then magnetically coupled pumps for seal-less applications. Magnetic drive couplings offer a non-contact transfer of torque. Use of these magnetic couplings will eliminate fluid or gas leakage from system components. Moreover, the magnetic couplings are also maintenance free, therefore reducing costs.

How are magnets allocated in a magnetic pump coupling to work?

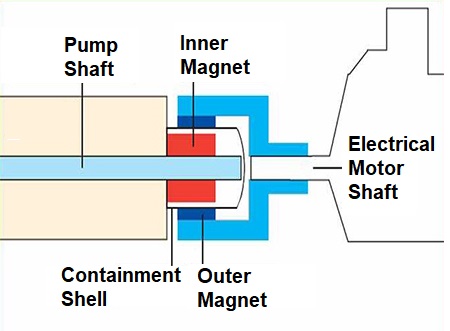

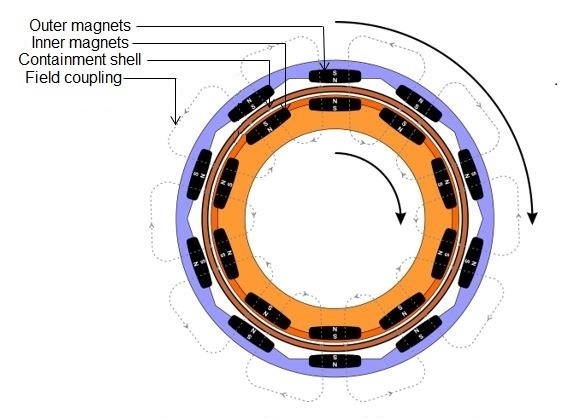

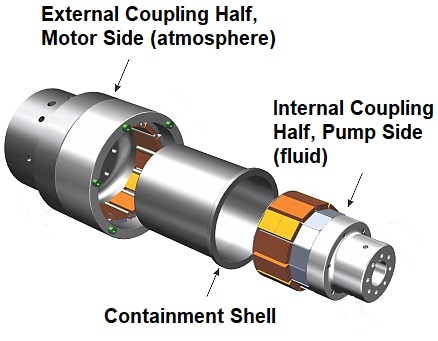

The coupled NdFeB or SmCo magnets are attached to two concentric rings on either side of the containment shell on the pump housing. The outer ring is attached to the motor’s drive shaft; the inner ring to the pump shaft. Each ring contains the same number of matched and opposing magnets, arranged with alternating poles around each ring. By driving the external coupling half, torque is transmitted magnetically to the internal coupling half. This can be done through the air or through a non-magnetic containment barrier, allowing complete isolation of the inner magnets from the outer magnets. There are no contacting parts in magnetic drive pumps which allows for torque transmission through both angular and parallel misalignment.

Why are NdFeB or SmCo rare earth magnets selected in magnetic pump couplings?

The magnet materials used in magnetic couplings are often Neodymium and Samarium Cobalt magnets with following reasons:

1. NdFeB or SmCo magnet is a type of permanent magnets, which is much easier to use than electro magnets which need external power supply.

2. NdFeB and SmCo magnets can reach much higher energy than traditional permanent magnets. Neodymium sintered magnet offers the highest energy product of any material today. Higher energy density enables lighter weight of less magnet material to reach improved efficiency of the whole pump system with compact size.

3. Rare earth Cobalt magnet and Neo magnet can work with better temperature stability. In the operation process, as working temperature is increasing or heating generated by eddy current, magnetic energy and then torque will have less reduce due to better temperature coefficients and higher working temperature of NdFeB and SmCo sintered magnets. For some special high temperature or corrosive fluid, SmCo magnet is the best choice of magnet material.

What’s the shape of NdFeB or SmCo magnets used in magnetic pump couplings?

The SmCo or NdFeB sintered magnets can be produced in a wide range of shape and size. For the application in magnetic pump couplings, mainly magnet shapes are block, bread or arc segment.

The main manufacturer for permanent magnetic couplings or magnetically coupled pumps in the world:

KSB, DST (Dauermagnet-SystemTechnik ), SUNDYNE, IWAKI, HERMETIC-Pumpen, MAGNATEX

Post time: Jul-13-2021